Industrial producer of apartment buildings

We have a scalable capacity of up to around 6,000 apartments per year, and deliver either turnkey buildings or modules to the construction site.

The traditional construction of apartment buildings is costly, time-consuming and unpredictable. We can significantly improve predictability, and reduce time and money, compared to conventional construction methods.

We deliver:

- Flexibility – Low mixture/high volume

- Streamlined process

- 90% completion to the construction site

- Cost savings

- Time savings, in all phases

- Scandinavian quality products Globally

SIBS Project process

By having control over the entire value chain, we can ensure everything from quality, delivery, production efficiency, and supplier management, resulting in cost-effectiveness and strong delivery capability.

SPS Flow

Design & configuration

SIBS has developed a dynamic configurator that automates the drawing process for modular buildings using predefined parameters. This provides greater flexibility in the drawing process than is possible using a conventional modular builder.

Time

Cost

Quality

Sustainability

Planning and resourcing

The automated drawing process means material components can be determined and ordered at an early stage, with very high precision and cost transparency. Just-in-time delivery to the factory of all materials in the right quantities dispenses with the need to hold large stocks.

Time

Cost

Quality

Sustainability

Production

The factories in Penang, Malaysia, receive digital drawings and material components and then build the housing modules in a streamlined, systematic and semi-automated process.

Production takes place in a controlled indoor environment. This guarantees quality and provides a better working environment for manual work elements that would otherwise be carried out at the construction site.

For a typical project, the modules are ready around 4–6 weeks after production start. A large number of standardised quality controls are performed during production. All materials and components installed in the apartments are registered to make them easily traceable.

Time

Cost

Quality

Sustainability

Logistics & transport

SIBS’ integrated logistics infrastructure manages shipping from Penang, Malaysia, all the way to the final destination at the construction site.

Large-scale procurement of freight shipment by land and sea before production begins allows for a high level of efficiency and cost transparency.

Time

Cost

Quality

Sustainability

Assembly & completion

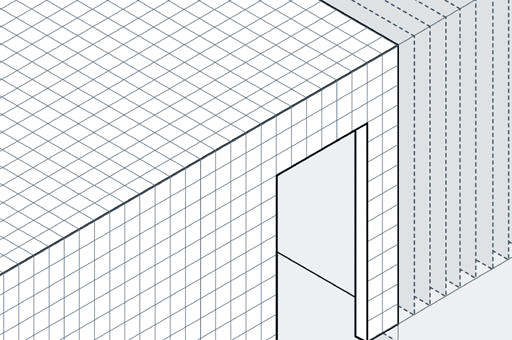

Ground work and foundations are completed while the modules are being produced in the factory and once the modules arrive at the construction site, assembly work begins on the completed foundations.

The modules are easy to assemble using SIBS-Connect, which also enables the modules to be lifted out and the building dismantled.

The facade and roof are fitted on site. On average, 20 modules are assembled per day.

Time

Cost

Quality

Sustainability

High Scandinavian quality, design and sustainability

Our residential apartments are constructed with a high Scandinavian quality standard, infusing modern design elements with quality materials.

The exteriors offer aesthetically pleasing design and our buildings are constructed with sustainability at their core, incorporating energy-saving measures like thermal isolated windows, rooftop solar panels and geothermal heating.

Our focus is on utilizing renewable resources, minimizing waste, and creating products that have a minimal impact on the environment.